Another name for lineman pliers – In the realm of tools, lineman pliers stand out as a versatile and indispensable companion. Also known as lineman’s pliers, these tools have a unique design and a wide range of applications, making them essential for various industries and tasks.

This comprehensive guide will delve into the world of lineman pliers, exploring their design, materials, applications, safety considerations, and more. Discover the versatility of these tools and how they can empower you to tackle any electrical or mechanical project with confidence.

Name Variations

Lineman pliers, also known as linesman pliers or electrician’s pliers, are a type of pliers specifically designed for electrical work. These pliers are commonly used by electricians, telecommunication technicians, and other professionals who work with electrical wires and cables.

In various industries or regions, lineman pliers may be referred to by different terms, such as:

Common Names

- Linesman pliers

- Electrician’s pliers

- Combination pliers

- Slip-joint pliers

Industry-Specific Names

- Telecom pliers (used by telecommunication technicians)

- High-voltage pliers (used by electrical workers dealing with high-voltage systems)

- Power lineman pliers (used by power line workers)

Regional Names

- Snips (in some parts of the United States)

- Side cutters (in some parts of the United Kingdom)

- Diagonal cutters (in some parts of Canada)

Design and Features

Lineman pliers, also known as linesman pliers or electrician’s pliers, stand out due to their distinctive design and specialized features. They are specifically crafted for electrical work, providing a combination of gripping, cutting, and twisting capabilities.

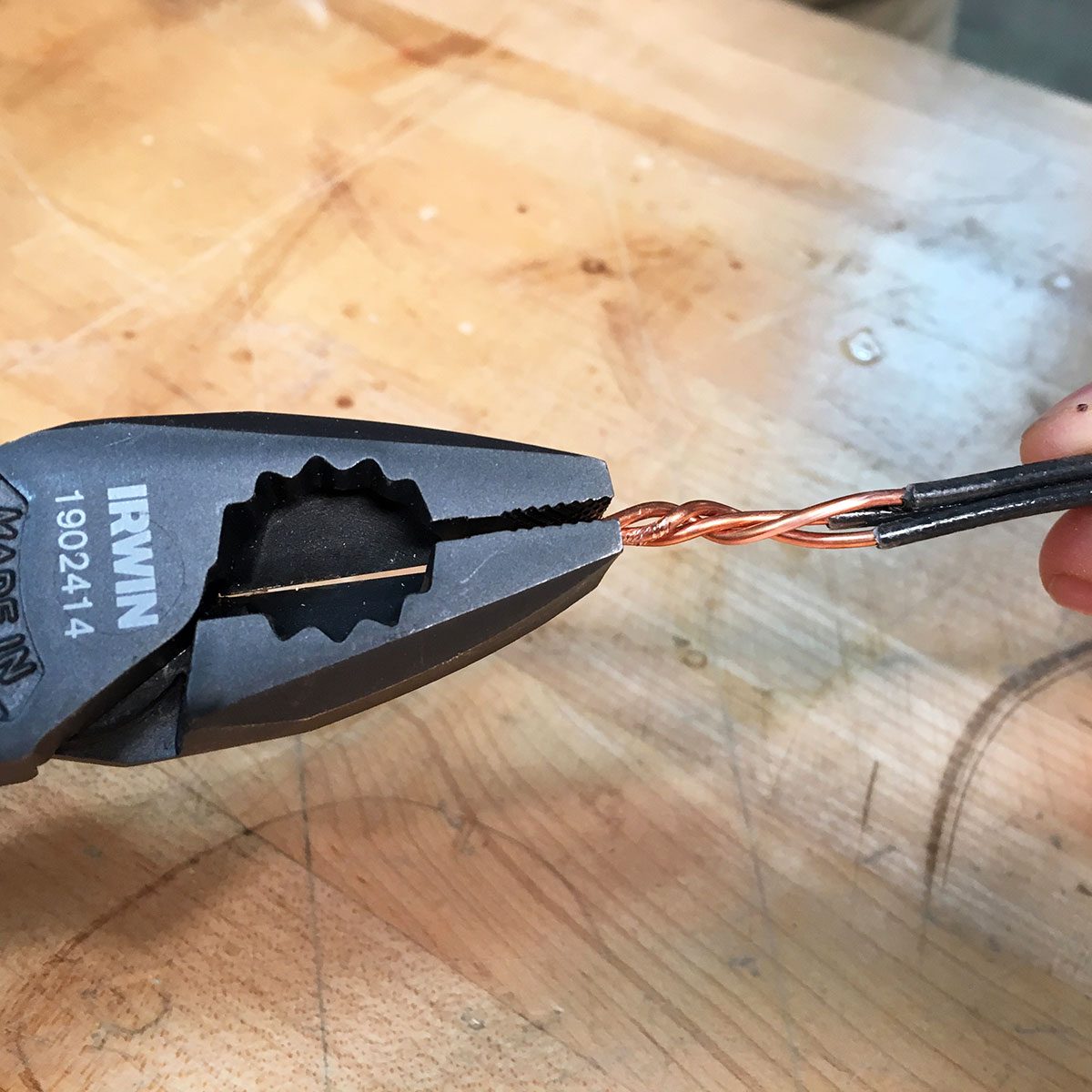

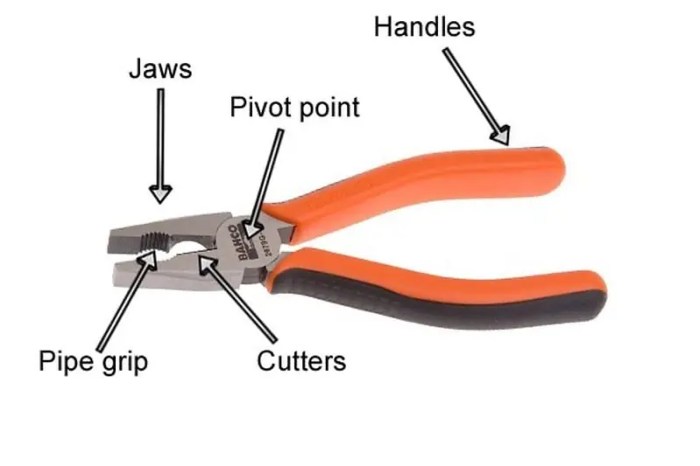

The pliers consist of two handles, typically insulated for safety, and a pair of jaws. The jaws are designed with multiple surfaces, each serving a specific purpose. The serrated inner surfaces provide a secure grip on wires and cables, while the flat outer surfaces are ideal for twisting and shaping.

The cutting edges, located near the base of the jaws, are hardened to ensure clean and precise cuts.

Handles

The handles of lineman pliers are designed for comfort and control. They are typically made of durable materials like rubber or plastic, providing a non-slip grip even in wet or oily conditions. The handles are often ergonomically shaped to reduce fatigue during extended use.

Jaws

The jaws of lineman pliers are the primary work surface. They feature a combination of serrated and flat surfaces to accommodate various tasks. The serrated inner surfaces grip wires and cables securely, preventing slippage. The flat outer surfaces are used for twisting and shaping wires.

Additionally, some lineman pliers have a built-in wire cutter near the base of the jaws, which is hardened for durability and precise cutting.

Cutting Edges

The cutting edges of lineman pliers are located near the base of the jaws. They are hardened to provide long-lasting sharpness and precision. The cutting edges are designed to cleanly cut through wires and cables of various gauges.

Materials and Durability: Another Name For Lineman Pliers

The materials used in the construction of lineman pliers play a vital role in determining their durability and longevity. Let’s explore the common materials and their impact on these pliers:

High-Carbon Steel

- Widely used for its strength, durability, and resistance to wear and tear.

- Undergoes heat treatment processes to enhance its hardness and toughness.

- High-carbon steel pliers are suitable for heavy-duty applications and can withstand substantial force without bending or breaking.

Alloy Steel, Another name for lineman pliers

- An alloy of steel with other elements, such as chromium, vanadium, or molybdenum.

- Offers increased strength and resistance to corrosion compared to high-carbon steel.

- Alloy steel pliers are ideal for demanding tasks in harsh environments.

Stainless Steel

- Contains chromium and nickel, which provide excellent corrosion resistance.

- Resists rust and oxidation, making it suitable for use in wet or corrosive environments.

- Stainless steel pliers may not be as strong as high-carbon or alloy steel but offer superior longevity in demanding conditions.

Applications and Industries

Lineman pliers, also known as linesman pliers, are indispensable tools in various fields. Their versatility and functionality make them a go-to choice for professionals in the electrical, construction, telecommunications, and automotive industries.

Electricians and electrical engineers rely heavily on lineman pliers for a wide range of tasks, including cutting, gripping, twisting, and stripping wires. Their high-leverage design allows for effortless cutting through tough cables, while the precision-machined jaws provide a secure grip on small components.

Construction Industry

In the construction industry, lineman pliers are used by carpenters, plumbers, and HVAC technicians. Their ability to grip and bend metal effortlessly makes them ideal for shaping conduit, cutting nails, and tightening bolts.

Telecommunications Industry

Lineman pliers are essential tools for telecommunications technicians who install, maintain, and repair telephone and data lines. They are used to cut and splice cables, crimp connectors, and tighten terminals.

Automotive Industry

In the automotive industry, lineman pliers are commonly used by mechanics and technicians for various tasks such as cutting wires, removing clips, and adjusting components. Their compact size and versatility make them a valuable addition to any mechanic’s toolbox.

Lineman pliers, also known as diagonal cutters, are a handy tool for electricians and other tradespeople. If you’re a crossword puzzle enthusiast, you may have encountered the clue “harper in far north” here . Returning to our discussion on lineman pliers, they are typically made of forged steel and feature sharp, beveled edges for cutting wire and other materials.

Safety and Precautions

When working with electricity, safety should be your top priority. Lineman pliers are no exception. Here are some guidelines to ensure your safety while using them:

Proper Handling

- Always wear insulated gloves and eye protection.

- Inspect the pliers before each use for any damage or wear.

- Never use pliers that are damaged or have loose joints.

- Use the correct size pliers for the job.

- Keep your hands away from the cutting edges.

Proper Storage

- Store the pliers in a dry place.

- Keep them away from children and pets.

Proper Maintenance

- Clean the pliers regularly with a damp cloth.

- Lubricate the joints occasionally with a light oil.

- If the pliers become damaged, do not attempt to repair them yourself. Take them to a qualified electrician.

FAQ Insights

What are the different types of lineman pliers?

Lineman pliers come in various types, including regular lineman pliers, long nose lineman pliers, and diagonal cutting lineman pliers. Each type is designed for specific tasks and offers unique advantages.

What are lineman pliers used for?

Lineman pliers are versatile tools commonly used in electrical work, telecommunications, construction, and other industries. They are ideal for cutting, gripping, twisting, and bending wires, as well as performing various other tasks.

What materials are lineman pliers made of?

Lineman pliers are typically made of high-quality steel alloys, such as chrome vanadium steel or carbon steel. These materials provide durability, strength, and resistance to corrosion.